Unmanned EOT Crane System Enhances Operational Efficiency via NISE 3900E AI Integration in the Steel Mill

Background

One of Taiwan’s largest steel corporation. The main products include plates, bars, electrical steel coils, and hot-dip galvanized coils. The company ships out steel coils that weigh tens of tons each. These 'heavy' loads are transported, processed, and shipped by the heavy-duty lifting device called the 'EOT Crane.' By moving horizontally and vertically in the factory area, it can lift and transport steel coils to designated positions, managing the schedule and transporting thousands of tons of steel coils in and out of the factory and warehouse.

Challenge

Operating the EOT Crane was used to require manual labor. Operators enter the driver's seat hanging from the ceiling to control the lifting and transport of steel coils. However, the environment is in high temperature and risky. Besides, human workers have limitations in terms of working hours, needing at least 4 hours of rest.

Once the EOT Crane malfunctions, it can lead to a complete halt in the entire production line, resulting in losses of up to million dollars. Manual inspections required regular maintainence. The onsite environment is extremely harsh. If people frequently go to the site for measurements, there are safety risks.

Solution

Machine Vision Analyzer: NISE 3900E

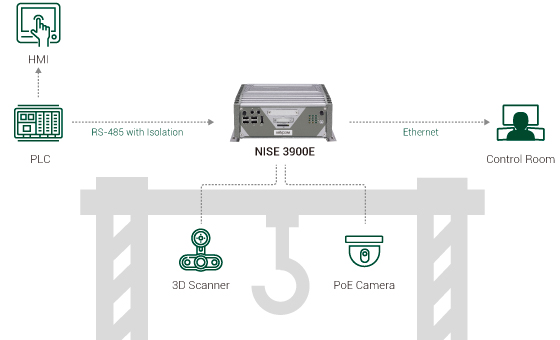

To overcome the challenges, the steel company developed an automated EOT Crane system by unmanned operation. The system is composed of PoE cameras, 3D scanner, industrial computer for machine vision(AI/ML algorithms) and communication, PLC and HMI.

The NISE 3900E, installed in EOT Cranes offers robust protection against a range of environmental challenges. Notably, it is equipped to handle wide temperature, shocks, and vibrations, making it particularly suitable for demanding and critical operating warehouse of the steel manufacturer. With COM port isolation design, NISE 3900E enhances the reliability of the system by preventing surge under harsh environment.

To create unmanned EOT crane, the cranes need machine vision. The steel company attempted to convert the visual information operators see into logical control commands through an IPC, which would then be interpreted and executed by the crane itself. NISE 3900E, Powered by 8th and 9th Generation Intel ® Core™ processors integrates high-resolution cameras and 3D scanners by PoE LAN ports as the image inputs for machine vision and maximums graphic processing performance by GPU cards on PCIe slots to effectively meet industrial AI requirements, from image processing/optimization to machine/deep learning and machine vision/object recognitioin.

The high-resolution cameras were installed on the unmanned EOT Crane to capture two-dimensional images of the trailer platform and the 3D scanner were able to reconstruct vertical coordinates on the two-dimensional images. This development made an huge improvement in computer vision technology . These images were then transmitted to a HMI used by the crane operator. The operator would indicate the storage position for the steel coils on the screen, and the control computer would automatically convert this storage position into coordinates and send them to the EOT Crane control system for lifting.

In addition to using a machine vision system to accurately position the steel coil storage slots, the company also developed various intelligent logistics-related technologies. These included optimizing the lifting schedule, calculating the best lifting path using AI, and establishing a queue optimization system for unmanned warehouses. This system could accurately predict operation times, allowing drivers to arrive at the warehouse at the appropriate times to perform loading and unloading tasks.

Furthermore, by analyzing the processes of hundreds of thousands of steel coils entering and leaving the warehouse, The steel company created an optimized storage slot prediction feature in their warehouse management system. This ensured that each steel coil could be delivered to the customer using the fewest lifting operations and shortest distance.

During lifting operations, The steel company designed a versatile smart lifting clamp that could identify the coil's identity, detect the center of the coil, and accurately lift and transport the steel coil. Additionally, the clamp featured an active safety protection mechanism. Utilizing deep learning technology, it could detect personnel movement within the EOT Crane's operating range, automatically identify and avoid obstacles.

Benefit and Result

Minimizing labor operations and management: Unmanned EOT Cranes can operate continuously for 24 hours without interruption. This automation even functions during the late hours of the night when all employees have left. With backend management methods, the system can also perform automatic stacking and inventory management the night before.

Optimizing Operation: After achieving full automation in lifting operations, the steel company interconnected their unmanned EOT Crane system with both logistics and information flows, reducing the need for additional manual operations and management. For example, by connecting the EOT Crane to logistics information, they could determine the coils required for the following day's shipment. The system would automatically rearrange the coils the previous night, lifting them to a position near the loading bay. This shortened the preparation time for the next day's shipment.

Alternatively, when a delivery driver checked in outside the warehouse, they could swipe an ID card. Once the driver's identity and vehicle number were confirmed, the warehouse management system would receive the mission details and automatically initiate the lifting task for the designated steel coils.

Reducing downtime and maintenance costs

The unmanned EOT Crane system can continuously monitor the condition of critical crane components, such as motors, gears, and brakes. By analyzing data from these components, AI can assess their health and performance, enabling maintenance teams to intervene at the right time and avoid catastrophic failures. AI can also identify abnormal behavior in crane operations by establishing baseline patterns and flagging deviations. If the crane's performance deviates from the norm, AI can issue alerts, allowing maintenance teams to investigate and address potential issues before they escalate into more significant problems.

Since its deployment in 2018, it has completed over 60,000 trips and lifted more than 300,000 steel coils. Following the success of the first system, the steel company introduced a second system in the same warehouse in November of last year. This warehouse can accommodate around 20,000 metric tons of steel coils, and with the two unmanned EOT Cranes, achieves full warehouse automation for steel coil lifting.

The steel company not only used this system for its own purposes but also exported it to the steel plants in China. In 2019, they sold 12 systems, and during the COVID-19 pandemic last year, they remotely assisted customers in system calibration and implementation.

Key Features for Application Needs

- Support 8/9th Gen Intel® Core™ i7/i5/i3 LGA socket type embedded processor

- Intel® Q370 PCH

- Support 1 x 2.5" SATA HDD

- 1 x DVI-D, 1 x DP, and 1 x HDMI with independent display support

- Three Intel® GbE LAN ports; support WoL, teaming and PXE

- 1 x External M.2 socket and 1 x SIM card socket

- 6 x USB 3.1 Gen 1, 4 x USB 2.0

- 2 x RS232/422/485 with auto flow control & 2 x RS232

- 1 x Internal mini-PCIe socket support optional Wi-Fi/3.5G/4G LTE

- Support +9V to 30VDC input; ATX power mode

- One PCIe x4 expansion