NDiS B560: Empowering Packaging Industry in the Digital Age

A leading French packaging company specializing in filling and packaging machines has undergone a remarkable digital transformation,

A leading French packaging company specializing in filling and packaging machines has undergone a remarkable digital transformation, using advanced technology to overcome operational challenges and enhance production processes. Faced with issues like inconsistent quality control, increased rework, unclear root cause identification, and process inefficiency, the company embarked on a game-changing journey that harnessed cutting-edge solutions.

Central to this evolution is the integration of the NDiS B560 fanless box computer, seamlessly fitting within their production lines. This pivotal technology allowed the implementation of an Automated Optical Inspection (AOI) system, a breakthrough for quality oversight. The NDiS B560-powered AOI system enables real-time data monitoring through high-resolution camera inspections, ensuring meticulous assessment of bottle shape, integrity, and cleanliness.

An outstanding feature of the NDiS B560 is its use of Intel® Core™ processors, providing the computational power necessary for robust graphics processing. This precision supports accurate evaluation of packaging quality, reinforcing the company's commitment to excellence.

Moreover, the NDiS B560 facilitates seamless transmission of inspection data via Wi-Fi and 4G/5G connectivity to a centralized database. This real-time data exchange has revolutionized remote management, swiftly identifying and addressing anomalies, ultimately streamlining production and maintaining stringent quality standards.

The successful integration of the NDiS B560 exemplifies the transformative potential of digital innovation in traditional sectors. As industries worldwide embrace digital transformation, the synergy between technology and tradition becomes a catalyst for improving consumer experiences. Offered by NEXCOM, the NDiS B560 goes beyond being a mere tool; it emerges as a conductor shaping the future of packaging through digital transformation.

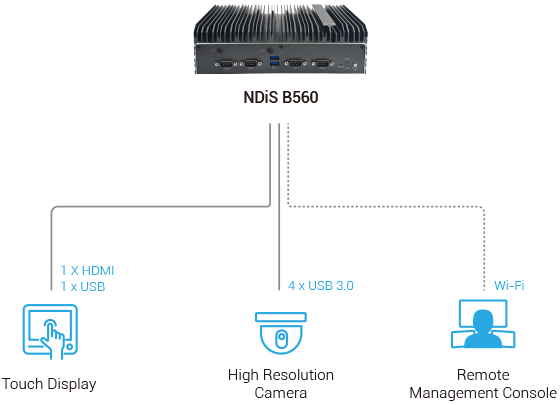

Application Diagram

Key Features for Application Needs

- Support 8th/9th Gen Intel® Core™ i9/i7/i5/i3 LGA socket type embedded processor, up to 35W

- Intel® Q370

- Intel® integrated UHD 630 graphic engine

- Support 3 independent 4K2K 60Hz display output

- Support 1 x 2.5” SATA HDD

- 3 x HDMI 2.0, 6 x USB 3.0, 2 x GbE LAN, 4 x COM, 1 x Line-out, 1 x Mic-in

- Support M.2 Key B/E/M

- Fanless design

- Support extended temperature -20~60°C